103rd Brewing and Engineering Conference 2016

International congress for the brewing and beverage industry – 7 to 9 March 2016, Soest, Germany (www.vlb-berlin.org/en). Deze week is er een congres over bierbrouwtechniek. Daar zullen vast allerlei Duitse brouwgeheimen worden besproken.

Ik had wel eens gehoord dat er gist werd gestolen en via een hoge hoed werd gesmokkeld, maar er zijn nog meer van dergelijke verhalen, zo lees ik in The Sword and the Armour: science and practice in the brewing industry 1837-1914 Ray Anderson:

Pils/Lager all over the world

At the German Brewing Congress of June 1884, the redoubtable Max Delbrück, Director of the Experimental and Teaching Institute for Brewing in Berlin announced ‘With the sword of science

and the armour of practice German beer will encircle the world.’ It was no idle boast. In 1887 beer output in the German states exceeded that in the UK for the first time and Germany became the

largest producer of beer in the world.

Fifty years earlier, when the 18 year old Victoria came to the thrown, it was unthinkable that Germany would hold such a position. Britain was the premier brewing nation, with London's massive porter breweries of ‘a magnificence unspeakable’ in the van.....over 70% of the beer sold is lager - and much of the ale and stout now served in pubs is dispensed at very low temperatures to make it seem more like lager! However, I doubt if Max Delbruck would recognise the lager of unrivalled blandness which now sells the most worldwide as having much to do with what he knew as

German beer (www.breweryhistory.com/journal/archive/123/Science.pdf).

(zie ook Brewer & Distiller International • May 2009 • www.ibd.org.uk Brewing history 25. www.ibdlearningzone.org.uk/article/show/pdf/483/ en www.yumpu.com/en/document/view/4177574/the-sword-and-the-armour-brewery-history-society)

Max Delbrück: Born 16 Jun 1850; died 4 May 1919 at age 68.

Max Emil Julius Delbrück was a German chemist who spent a forty-five year career leading development in the fermentation industry. He established a school for distillation workers, a glass factory for the manufacture of reliable apparatus and instruments, and an experimental distillery. Giving attention to the raw resources, he founded teaching and experimental institutions to improve cultivation of potatoes and hops. He researched physiology of yeast and application in the process of fermentation, production of pure cultures, and the action of enzymes. He started the journals Zeitschrift fur Spiritus-Industrie (1867) and Wochenschrift für Brauerei, for the alcohol and brewery industries, which he co-editted. His nephew, also named Max Delbrück, became a microbiologist who won the Nobel Prize in Physiology or Medicine in 1969 (http://todayinsci.com/6/6_16.htm#DelbruckMax1850). Lactobacillus Delbrücki herinnert aan hem (Wie wir das Leben nutzbar machten: Ursprung und Entwicklung der Biotechnologie, Robert Bud).

Mit dem Schwerte der Wissenschaft, mit dem Panzer der Praxis, so wird Deutsche Bier die Welt erringen.

(With the sword of Science and the armour of Practice, German beer will encircle the world.)

— Max Delbrück

From address about yeast and fermentation in the brewery, to the German Brewing Congress (Jun 1884) as Director of the Experimental and Teaching Institute for Brewing in Berlin. In 'Ueber Hefe und Gärung in der Bierbrauerei', Bayerische Bierbauer, 1884, 19, 312. As cited in Ray Anderson, Brewery History (Summer 2006), No. 123, 55. Indeed, as quoting Anderson, “In 1887 beer output in the German states exceeded that in the UK for the first time and Germany became the largest producer of beer in the world.” Using Google translation, the word “armour” might also be read as “breast-plate.” (http://todayinsci.com/QuotationsCategories/B_Cat/Beer-Quotations.htm).

Techniek en spionage

Once the steam engine became available, London brewers where understandably keen to adopt it. By

the turn of the century the improved engines of Boulton and Watt and others had been installed in all but one of London's major breweries and horses and men were reduced in number.

Quantitative measurement crept into brewing from the mid 18th century with the application of the thermometer by Michael Combrune, and then the hydrometer, in the form of the saccharometer, by John Richardson.

...

Until the 1840s bottom-fermentation was unknown outside Bavaria and Bohemia (where it had been practised since about 1400). It was then, instigated to an extent by the efforts of Gabriel Sedlmayr jnr from the Spaten Brewery in Munich and Anton Dreher from his family brewery at Schwechater just outside Vienna, that lager began to spread. On a trip to Britain in 1833 the pair had indulged in what has been described as industrial espionage, learning the use of the saccharometer and thermometer and the techniques of large scale brewing. They were not above rather underhand behaviour such as secretly taking samples in breweries using hollow walking sticks. On their return home Sedlmayr and Dreher became apostles for lager and applied what they had learnt in Britain's more advanced ale breweries to the production of bottom-fermented beers. The first pale straw coloured lager, for the product of Munich was dark brown in colour and that of Vienna a reddish brown, is usually ascribed to Josef Groll a German brewer working in Pilsen in October 1842. Lager was first produced in Norway in 1843 and more famously Jacob Christian Jacobsen made the long journey from Copenhagen to the Spaten brewery in 1845 and obtained some yeast which he carefully preserved in his hat box on the return journey and used it to produce his first lager (a dark one) in 1846. A year later he built a new brewery on a hill overlooking Copenhagen and called it after his young son Carl and its location: hence Carlsberg. Lager was making significant inroads in north Germany by 1850 and Gerard Heineken, seeing which way the wind was blowing, switched from ale to lager brewing in Amsterdam in 1869.

Lager was to be found on the other side of the Atlantic from the 1840s. Frederick Pabst, Frederick Miller and Joseph Schlitz exploited Lake Michigan's ice for lager production. Bernard Stroh similarly on Lake Erie. Ebrehard Anheuser and Adolphus Busch utilized the cool caverns of St Louis. Adolph Coors the Colorado mountains. From the 1870s these German-Americans developed a new style of lager brewed with readily available cereals, notably maize (corn) and in Anheuser-Busch's case rice as diluants for the high nitrogen six-rowed barleys grown in the USA. These adjuncts were used unmalted and were gelatinised before addition to the malt mash. Although banned in Bavaria, there was nothing new in the use of unmalted adjuncts, but what was different from mainstream European practice was the high level of use. The Americans used them at levels of 50% or more of the grist. This coupled with the development of an accelerated brewing process where storage time was minimised and filtration used for clarification, led to the development of unique very pale coloured, delicate, beers (www.breweryhistory.com/journal/archive/123/Science.pdf).

November 2015 was an auspicious month for the American beer industry. According to data provided by the Brewers Association the number of breweries in the United States reached 4,144. At no other time in our country’s history has America had so many breweries. The previous high was 4,131 in 1873. ...In commenting on reaching a record high number of breweries Bart Watson, the Brewers Association’s economist, stated that “this is a remarkable achievement, and it’s just the beginning”. Some may find the statement by Watson to be provocative as it suggests that the number of breweries is set for continued significant growth (http://www.thebeerprofessor.com/?p=1477#more-1477). De uitspraak van Watson kan wellicht ook wel worden vergeleken met die van Delbrück, maar Max Delbrück was nog bouder, aangezien Amerikaans bier reeds behoorlijke aanzien heeft in de brouwerswereld.

1873 – the year in which Jules Verne’s Around the World in 80 Days was published in France, Levi Strauss and Jacob Davis patented the first blue jeans with copper rivets, Prince Edward Island became the seventh Canadian Province, nineteen students attended the opening class at The Ohio State University, and Jesse James and his gang committed the world’s first robbery of a moving train near Adair, Iowa.

But what about beer? What was happening in the world of beer in and around 1873? While the number of breweries today is almost identical to 1873 the population of the United States was considerably smaller back then – ~40 million, compared to ~320 million today. Do the math and that means that in 1873 there was 1 brewery for every 9,683 people, compared with 1 brewery for every 77,220 people today. In 1873 there were 8.9 million barrels of beer produced in the United States. Today’s craft brewers produce 22.3 million barrels. In 1873 the top three beer producing states were New York (2.9 million barrels), Pennsylvania (1.1 million barrels), and Ohio (0.8 million barrels). Today the top three beer producing states (for craft beer) are Pennsylvania (4.1 million barrels), California (3.4 million barrels), and Colorado (1.7 million barrels).

The breweries of the 1870s were smaller than the craft breweries of today. In 1873 the average annual output of American breweries was 2,154 barrels. Today’s craft brewery averages 5,381 barrels. This can be partly explained by the fact that a number of today’s breweries have a much larger geographic reach than the breweries of the 1870s (www.thebeerprofessor.com/?p=1477#more-1477). Today’s craft breweries have access to brewing techniques and transportation technology and infrastructure that were unavailable (or was just becoming available) to brewers in the 1870s. The process of pasteurization*, which kills harmful bacteria in the beer with the result that it does not spoil so quickly, was discovered* by French chemist Louis Pasteur* in 1864. In was during the 1870s that Anheuser-Busch, and other brewers, started to pasteurize their beer. Pasteurization opened up the possibility of brewers shipping their beer beyond very local markets (www.thebeerprofessor.com/?p=1477#more-1477). * Over pasteurisatie zo meer...

From the 1860s, the increasing availability of efficient artificial refrigeration freed lager brewers from the need for natural ice. Lager and ale brewers alike adopted all year round brewing. Refrigeration was initially used to produce ice but was soon applied to direct cooling via expansion coils (www.breweryhistory.com/journal/archive/123/Science.pdf).

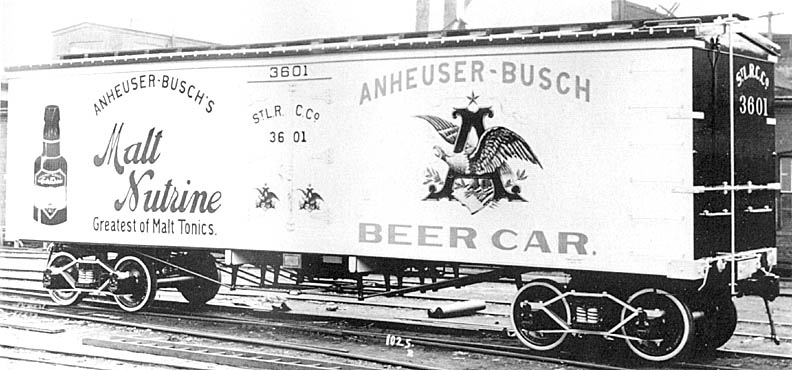

Anheuser-Busch was one of the first companies to transport beer nationwide using railroad refrigerator cars (https://en.wikipedia.org/wiki/Anheuser-Busch).

When beer was transported to more distant markets it was done so by rail car. The rail network of 1870 was confined primarily to those parts of the country that lay east of the Mississippi River.

Another key transportation innovation that made its appearance in the 1870s were refrigerated rail cars. Anheuser-Busch started using refrigerated rail cars in 1874 and by 1877 had a fleet of forty rail cars, manufactured by the Tiffany Refrigerator Company of Chicago, that were used to deliver beer to ever more distant markets. The first refrigerated rail cars were cooled by using huge amounts of ice. This meant that there had to be Ice Houses (where rail cars would replenish their ice supplies) located at strategic locations along the rail track. It was not until the early-1880s that Anheuser-Busch adopted artificial refrigeration systems, thus eliminating their dependence on ice. By 1879 Anheuser- Busch’s beer was available in all thirty-eight states in the Union.

So what type of beer were Americans drinking in 1873? By then lager was the most popular style of beer in the United States. Lager was introduced to the United States by German immigrants who started coming to the United States in large numbers beginning in the 1830s. Prior to that British-styled ales and stouts had dominated the American beer market. By 1880 over eighty percent of the brewers in the United States were German immigrants. While the lagers brewed by the first-wave German immigrants were replicas of those brewed back in the old country the American beer drinker demand lager that was blander and smoother – hence the utilization by the brewers of cheap adjuncts, particularly rice. By the end of the 1870s lager was well on its way to becoming Americanized (www.thebeerprofessor.com/?p=1477#more-1477).

During the 1870s, Adolphus Busch toured Europe and studied the changes in brewing methods which were taking place at the time, particularly the success of pilsner beer, which included a locally popular example brewed in Budweis. In 1876, Busch introduced Budweiser, with the ambition of transcending regional tastes. His company's ability to transport bottled beer made Budweiser the first national beer brand in the United States, and it was marketed as a "premium" beer.

The company was renamed Anheuser-Busch Brewing Association in 1879; in 1880, Adolphus Busch became company president upon Anheuser's death. The Busch family fully controlled the company through the generations until Anheuser-Busch's sale to InBev in 2008 (https://en.wikipedia.org/wiki/Anheuser-Busch).

Lager now became a world drink. The first successful commercial brewery in Japan, the Spring Valley Brewing Company set up in Yokohama by an American W. Copeland in 1869, evolved into the Kirin Company and brewed lager. German brewmasters brought brewing to China for the first time in the 1870s; Tsingtao lager from what is now China's biggest brewer, was an early product. Hampered by lack of suitable materials and the climate, local beer production in Australia only started to outstrip imports in the 1870s. Lager brewing reached the country in the late 1880s, with the American émigré Foster Brothers beer, brewed by the German brewmaster they brought with them using domestic cane sugar as an adjunct to malt, going on sale in Melbourne in 1889.

Lager had been imported into Britain since about 1850 and the first tentative steps at brewing what at least was called lager, may have been taken place within a decade or so thereafter but the evidence for these early attempts is sketchy. Experimental brewing of genuine lager took place at William Younger's Holyrood brewery in 1879 and what was probably the first purpose built lager brewery in the UK was built in Wrexham in 1882. Tennents started brewing lager in Glasgow in 1885. But it remained very much a niche drink in the UK (about one percent of the UK market in 1960, by which time lager made up c. 20% of the market in Scotland) (www.breweryhistory.com/journal/archive/123/Science.pdf).

![]() Louis Pasteur, de microscoop en gist

Louis Pasteur, de microscoop en gist

Louis Pasteur (December 27, 1822 – September 28, 1895) was a French chemist and microbiologist renowned for his discoveries of the principles of vaccination, microbial fermentation and pasteurization. He is remembered for his remarkable breakthroughs in the causes and preventions of diseases, and his discoveries have saved countless lives ever since. He ... created the first vaccines for rabies and anthrax. His medical discoveries provided direct support for the germ theory of disease and its application in clinical medicine. He is best known to the general public for his invention of the technique of treating milk and wine to stop bacterial contamination, a process now called pasteurization. He is regarded as one of the three main founders of bacteriology, together with Ferdinand Cohn and Robert Koch, and is popularly known as the "father of microbiology". (https://en.wikipedia.org/wiki/Louis_Pasteur,

www.biography.com/people/louis-pasteur-9434402).

Concurrent with the spread of lager brewing came more emphasis on a scientific approach to brewing, the most famous early practitioner being Louis Pasteur. Until Pasteur carried out his investigations on wine and beer fermentations in the 1860s and 1870s and showed the importance of eliminating deleterious bacteria, there was little practically useful advice available to brewers on how to prevent their beers unaccountably going off. In a wider context, it was through the investigation of the production of wine, vinegar and beer that Pasteur established the importance of micro-organisms in causing disease. The far reaching significance of Pasteur's work on fermentation can thus not be doubted.

What is less clear is the actual impact his work had upon fermentation practice and brewing in particular. Pasteur's Etudes sur la Biere published in 1876 and translated into English as Studies on

Fermentation in 1879, is often cited as revolutionising the industry. This is something of an exaggeration. The fermentation technology he devised, which essentially involved aseptic procedures in a closed vessel, found very limited application. His advocacy of the danger of aerial infection in breweries found more adherents, but in time it became clear that a greater hazard came from contact of wort with dirty surfaces and the drip of germ-ridden condensations. Even the heat treatment technique which bears his name and which became so widely used was not recommended by him for use with beer on the grounds that it spoilt the flavour*. It is in his advocacy of the practical utility of science which he communicated in a very high profile manner, rather than in the detail of Pasteur's

work on beer where we may detect his real impact on the brewing industry. One undoubted practical outcome of Pasteur's work, however, was the growing adoption of that great Victorian gentleman's high tech. plaything, the microscope, for use in breweries. Pasteur was not the first to use a microscope in a brewery, but it was certainly he who popularised it.

Meer wetenschappers met microscoop en gist, stikstof, pH, microbiologie en botanica

A technology which was quickly accepted in most quarters of the brewing world was pure yeast culture introduced by Emil Christian Hansen at Carlsberg in 1883. Where Pasteur had identified bacteria as the causes of brewing problems, Hansen extended this to the presence of harmful yeasts. Pasteur had purified yeasts by acid washing to kill the bacteria. Hansen selected a single strain of yeast from the unreliable and variable mixed cultures then in use in the brewery and in so doing significantly improved the consistency of fermentations and the reproducibility of beer flavour (www.breweryhistory.com/journal/archive/123/Science.pdf).

Johan Kjeldahl

The head of the Carlsberg Laboratory’s chemistry department from 1876 to 1900. He developed a technique for the quantitative determination of nitrogen in chemical compounds and raw materials, still known today as the Kjeldahl method (www.carlsbergfondet.dk/en/Afdelinger/Carlsberg%20

Laboratorium.aspx). De Kjeldahl-methode is een methode geschikt om de fractie organische stikstof in chemische substanties te bepalen. De methode zal Kjeldahl-stikstof, dit is de hoeveelheid stikstof die in organische verbindingen vervat zat en de hoeveelheid ammoniak in het staal, weergeven, maar alle stikstof die in de vorm van nitraten en nitrieten gebonden is, wordt genegeerd.

Deze methode werd ontwikkeld door de Deen Johan Kjeldahl in 1883, terwijl hij voor de brouwerij Carlsberg werkte (https://nl.wikipedia.org/wiki/Kjeldahl-methode).

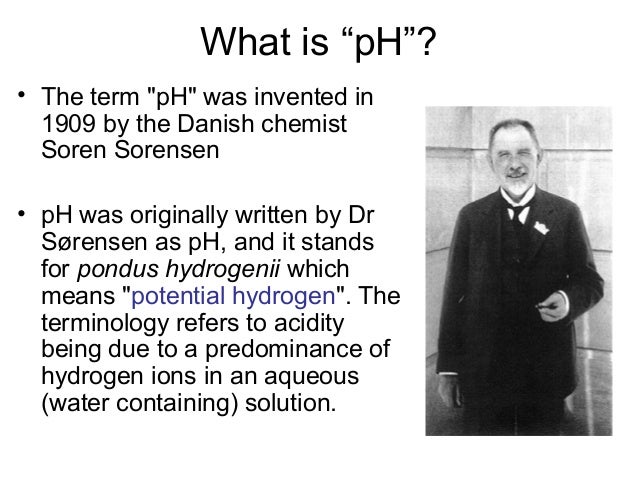

S.P.L. Sørensen

The head of the Carlsberg Laboratory’s chemistry department from 1901 to 1938. He introduced the concept of pH to describe a solution’s acidity and demonstrated the importance of this measure in understanding biochemical reactions, generally as well as in the context of brewing beer (www.carlsbergfondet.dk/en/Afdelinger/Carlsberg%20Laboratorium.aspx). Søren Peter Lauritz Sørensen (Havrebjerg, 9 januari 1868 – 13 februari 1939), in Denemarken ook bekend als S.P.L. Sørensen, was een Deens chemicus. Hij introduceerde het begrip pH als maat voor de zuurgraad. Hij was directeur van het prestigieuze Carlsberg Laboratorium, dat werd gesponsord door de brouwerij Carlsberg. In die tijd onderzocht hij de invloed van de ionenconcentratie op de analyse van eiwitten. Hierdoor ontwikkelde hij zich tot een expert op het gebied van de thermodynamica van de eiwitchemie. Een belangrijk resultaat van Sørensens werk was de definitie van de pH-schaal in 1909, waarmee voor het eerst de zuurgraad op een eenduidige manier kon worden weergegeven. Zijn naam is voorts verbonden aan de naar hem genoemde Sørensenbuffer en de als "natriumoxalaat volgens Sørensen" bekendstaande standaardoplossing voor titraties (https://nl.wikipedia.org/wiki/S%C3%B8ren_S%C3%B8rensen).

Beer is a beverage that is produced in a multistage process, where some stages of that process are intentionally influenced by microorganisms, while at other stages of the production process microorganisms are actively discouraged. Most of the intentional microbial activity is facilitated by yeast; however bacteria also play an influential role in beer production. This paper will describe the beneficial role of bacteria in the beer production process (the Good), but will also pay due attention to the negative influences bacteria might have on the quality of beer as a commodity (the Bad), and the properties of beer that have given it the status of an inherently safe food for human consumption with regards to disease-causing bacteria (the Ugly). Copyright © 2013 The Institute of Brewing & Distilling (Bacteria in brewing: The good, the bad and the ugly, Journal of the Institute of Brewing Volume 118, Issue 4, pages 335–345, December 2012 (Frank Vriesekoop et al.)).

What is clear is that the presence of an in-house laboratory in the 1880s was not particularly determined by the size of the brewery. Certainly many of the smallest breweries lacked such a facility, but so did the biggest of them all, Guinness, which had no laboratory when Barnard visited Dublin and would not have one until the 1890s. Nor does Barnard note a laboratory in most of the big London breweries. Indeed, Courage, Reid, Meux, City of London, and even Whitbread with their much vaunted Pasteur connections, do not even have a bench in the brewers' office by Barnard's account. One wonders what had happened to the legendary microscope the directors of Whitbread are said to have bought after Pasteur's visit to the brewery in 1871?....The first brewery research laboratory in the UK was established by Guinness in 1901. After five year's of allowing free publication when run by Horace Brown (ex Worthington's) this became a very secretive place, with

Guinness banning its staff from publishing anything of their work. The ban lasted for 40 years

(www.breweryhistory.com/journal/archive/123/Science.pdf).

Horace Tabberer Brown (20 July 1848 – 6 February 1925) was a British chemist....He started work at the Worthington Brewery in 1866. His focus was to solve practical brewing problems by employing and developing fundamental scientific principles. His research work considered barley germination, beer microbiology, water composition, oxygen and fermentation, beer haze formation, wort composition and beer analysis.

A true polymath, he left his mark on virtually all areas of science as applied to brewing, in a career which lasted over 50 years. His earliest work concerned treatment of sewage and analyses of the Burton waters. Later he took up study of geology, being led to it by pressing requirements in connection with the water supply of Burton. This entailed a good deal of field surveying, which was embodied in a paper on the Permian Rocks of the Leicestershire Coalfield (https://en.wikipedia.org/wiki/Horace_Tabberer_Brown).

Born on the 20th July 1848, Horace Tabberer Brown was the posthumous son of Benjamin Tabberer....he had a ...younger half brother Adrian Brown who also became an eminent brewing scientist, being appointed the first professor of brewing at Britain’s first university brewing school, after 25 years as the chemist at Salt and Co....He was friends with many scientists, including Dr Henry Böttinger, then manager of Allsopp’s brewery, who had a profound influence on Horace:

“He used often to express a firm and certain belief that the principles of brewing, which at that time were based, like those of many of the sister arts, on mere empiricism, would in time come to admit of a rational and scientific explanation … These conversations with Böttinger had the effect of arousing in me a great desire and ambition to help on the good cause, and if I have been able in any way during the last 50 years to assist in this, it is in great measure due to the sowing of good seed by an old and valued friend in ground which I trust has not been altogether stony and unproductive.”

On the 1st Jan 1866 at the age of 17 ½ he became the junior (3rd) brewer at Worthingtons, a brewery next door to his father’s house. In those days brewing was seasonal between October and May but the hours were long. He worked 12 hours a day, six days a week but still continued his lab studies at home during afternoons when on late shift in a small laboratory his dad built him.

His colleagues were “old school” and suspicious of science and “theorists”, the only science he was initially allowed to carry out was determining original gravity, and the weighing equipment for that was purchased....When he was allowed to establish a small lab at the brewery, it was on the condition that the windows were obscured so as not to scare customers that the beer was being doctored! According to Barnard, this was the first brewery in the world to use a microscope.

At this time many advances were being made in microbiology, and the fermentation industries were in the forefront of this. Advances in brewing science were applicable across range of areas such as medicine, surgery and sanitation, the study microorganisms in diseases of beer lead to insights in the microorganisms of diseases in people. For example, Pasteur’s “Studies on Beer” lead directly to his work in infectious diseases.

Another example of the cross over was Horace Brown being able to apply his knowledge to improving the sanitation in Butron-upon-Trent. At close of brewing season in 1868 he spent a few weeks at Frankland’s laboratory studying water analysis and then analysed the well waters at Worthington and other breweries, as well as the parish pumps and the Trent. He found many traces of sewage and was able to clean up the local water supply.

In 1869 he started to use a microscope in the brewery looking at yeast and soon after he read Pasteur’s “Studies on Wine”: “The immediate effect was that of a ray of light piercing the darkness and illuminating a new path into the unknown.”…

“In a short time, by a comparative study of the sediments of normal and faulty beers of various ages I had worked out, and could recognise, the particular organisms which produce most of the irregularities of bacterial origin.”

He discovered by microscopic examination that a horrible off flavour in beer similar to corked wine called “caskiness” or “fustiness” was caused by a Penicillin sp. growing on the wood of the casks.

His rigorously study of microorganisms found in sour beer meant that by 1873 he was able to recognise many beer spoilage organisms and the effects they’d have. He became an expert on Saccharobacillus Pastorianus (now Lactobacillus brevis) which caused 90% of the problems in Burton stock beers. His old school colleagues were still blaming the water or “some obscure electrical agency” and the brewing text books of the time were little better.

....

Due to his rigorous work when Pasteur’s “Studies on Beer” came out in 1876 he was probably already ahead of him in his knowledge. It was in this year that Brown was one of the founders of the “Bacterium Club”, an informal dining society of men interested in science. Far-reaching discussions were held on recent discoveries in chemistry and biology, particularly as they pertained to brewing, though a couple of medical doctors were also members.

By 1877 Brown had learnt that problems with beer were could be caused by yeast strains as well as bacteria and was aware of the role of “secondary” yeasts in the normal British brewery fermentations of the time, long before Claussen’s work on Brettanomyces. This later lead to a dispute with Hansen, the developer of pure single strain brewers’ yeast, as Brown was adamant that:

“…. the beers from the pure yeast, unless stimulated by the addition of a little diastatic malt-extract at the time of racking, were slower in conditioning than the corresponding samples from the ordinary yeast”

Brown correctly observed that: “primary yeast demands a crystallisable sugar like maltose or dextrose to keep it going, the secondary yeasts are capable of hydrolysing and utilising malto-dextrins and dextrins which the primary yeast cannot touch unaided by some extraneous ferment.”

He also developed an early method of removing contaminating bacteria by acidifying wort.....In 1883 his studies turned to the geology of Burton and for four years he studied the composition of the local landscape and the chemistry of the water, leading to an article published in 1889, the same year he was made a Fellow of the Royal Society.

He looked at barley germination between 1885-6, and gave a scientific basis to the previously empirical world of malting. In 1890 he published with his assistant GH Morris their findings in a major paper in the Journal of the Chemical Society called “Research on the germination of the Gramineae”.

...

Brewers had known for some time that dry hopping in cask encouraged secondary fermentation and ensured good condition in the beer. Browns systematic research into exactly why this was led further than even he envisaged. He found hop strobiles contained a diastatic enzyme, which broke down some of the dextrins in the beer to fermentable sugars. This lead to further research, for if diastase was present in hop strobiles was it present in all leaves?

Detailed botanical investigations into plant physiology followed, culminating in another important paper with Morris in 1893 on “The Chemistry of Foliage Leaves”....His initial enquiry into dry hopping ended with him winning a prize from the Royal Society and ultimately giving the 1905 Bakerian lecture on “The Reception and Utilization of Energy by the Green Leaf.”

...

In 1901 he was employed by Guinness to set up a research laboratory. He started work investigating “The Nitrogen Question” in beer, looking to see if careful control of the nitrogen level and composition of beer could control the growth of contaminants. The findings of research at the Guinness laboratory were only published privately, and due to a policy change the lab was closed in five years later.

In 1903 he was awarded the Royal Medal of the Royal Society “For his work on the chemistry of the carbohydrates and on the assimilation of carbonic acid by green plants”.

His researches on “The Nitrogen Question” continued after he had left Guinness but ultimately he had to conclude that beer infection could not be controlled by the nitrogen content.

...

He frequently travelled to America as he was director of an American brewing company, though I’ve yet to find out which one. He lectured to the Institute of Brewing on American techniques of bottling filtered beer and investigated the effects of head space oxygen content on shelf life.

...

[Horace Brown] died on the 5th February 1925, the most respected and highly awarded British brewing scientist (http://edsbeer.blogspot.nl/2013/09/horace-tabberer-brown.html).

Wetenschappers van brouwerijen en suiker

At Allsopp's there was Peter Griess who was their chemist for 25 years until his death in 1888. He fulfilled a full role as a chemist in the brewery, but he also had an abiding interest outside the day job - synthetic organic chemistry on which he published over 100 original papers and became a world authority. He is regarded today by historians of chemistry as a chemist of the first rank, whose work laid the foundations of the dyestuffs industry.

At Bass there was Cornelius O'Sullivan, he spent 40 years with the company until his death in 1907. He made his name in carbohydrate chemistry, the enzymology of the mash tun, closely associated with his brewing work.

At Worthington there was Horace Brown, a botanist, who did ground breaking work on barley germination and worked for thirty years for the company before falling out with the redoubtable Arthur Manners.

Finally there was Adrian Brown, Horace's somewhat less talented younger half-brother, who specialised in problems to do with yeast, and spent 25 years with Salts brewery before becoming the first professor of brewing at the newly formed Birmingham University in 1899. All four men were elected Fellows of the Royal Society

The number, if not necessarily the quality, of brewers' chemists was gradually to increase as the 19th century drew to a close. Employment of chemists in breweries then received a boost, somewhat indirectly, by an unexpected consequence of the implementation of the 'Free Mash Tun Act' of 1880. This piece of legislation changed the basis on which duty was paid on beer. For the previous fifty years duty had been levied on the raw materials (primarily malt; sugar had been allowed since 1847 but was not particularly advantageous to use because of duty differentials), now it was to be levied

directly on beer. Brewers were now free to use any wholesome source of extract they wished. This led them to employ 'malt substitutes' which soon made up around 20% of the grist for many beers.

Flaked maize and rice were commonly used 'adjuncts', but many brewers preferred the added convenience of ready made processed 'brewing sugars'. In 1900, twenty years on from the 'freeing'

of the mash tun, the use of brewing sugars from one particular manufacture, Bostock & Co., led to probably the great- est tragedy to affect the brewing industry in England. This came about when sul- phuric acid contaminated with arsenic was inadvertently used in the production of glucose and invert-sugar. The sugar was used to brew beer over a period of some nine months before its effects were spotted. Seventy people died and at least 6000 others had symptoms of arsenic poisoning. On the positive side, the affair led to the realisation that arsenic, at low but not negligible levels, was present in many batches of malt due to the fuel used for kilning. Indeed it is likely that arsenic poisoning from this source had been an unrecognised danger for gener- ations before the poisonings of 1900. The Royal Commission appointed to investi- gate the matter established the concept of the maximum permitted level of mate- rials in foodstuffs. Arsenic being the first environmental hazard to be con- trolled in this way. The scare also led to much work for chemists, particularly con- sulting chemists who made a pretty penny out of it. But, it also led brewers increasingly to recognise the virtues of having a chemist on site to test materials for safety as well as brewing value. This also made sense in economic terms. The brewers had been stung by the amount they had needed to pay consultants dur- ing the arsenic scare, why not have their own man on site who may well be useful in other ways? The growth in the lighter running beers and bottled beer trade which required more attention added strength to this view (www.breweryhistory.com/journal/archive/123/Science.pdf).

(https://ancoatsdispensary100.wordpress.com/2014/12/14/78-a-barrel-of-poisoned-beer/)

In 1900 a poisoning epidemic rocked Lancashire, being felt especially keenly in Manchester and Salford. At first the cause of the poisoning was not fully realised, victims were assumed to be suffering from alcohol related complaints, such as peripheral neuritis – a condition which resulted from chronic alcohol poisoning and was characterised by muscle paralysis and loss of function in sensory nerves. Alcohol was indeed the cause but not in the way initially envisaged.

Beer had been contaminated with arsenical acid, present in glucose and invert sugar (traced to a company of sugar refiners near Liverpool) which had been manufactured from sulphuric acid containing arsenic (from a firm in Leeds)...Dr Reynolds of the Crumpsall Workhouse who first realised that it was arsenic, not alcohol which was the root cause of the epidemic, (https://ancoatsdispensary100.wordpress.com/2014/12/14/78-a-barrel-of-poisoned-beer/) (The Arsenic Century: How Victorian Britain was Poisoned at Home, Work, and Play, James C. Whorton).

Deze epidemie werd door de Pure Beer Movement aangegrepen om hun ideologie uit te dragen dat bier enkel maar met 4 ingreidënten mag worden gebrouwen: mout, gist, hop en water (een Brits Reinheitsgebot). Deze methode was traditioneel, maar in 1847 had het parlement toestemming gegeven aan de brouwers om mout te vervangen door suiker. In 1880 werd het 'free mash tun' systeem ingevoerd, waardoor brouwers vrijheid kregen om ook andere zetmeelbronnen dan gerstemout te gebruiken, op voorwaarde dat het niet gevaarlijk was. De voorstellen zoals een Pure beer Law waren echter in de ogen van de bierindustrie onbetaalbaar. Ook een rapportage uit 1899 gaf aan dat een strenge wet onnodig was aangezien de kans dat als er al iets fout zou gaan met het brouwen, het zo verdund zou zijn dat er geen gevaar voor de volksgezondheid zou zijn (The Arsenic Century: How Victorian Britain was Poisoned at Home, Work, and Play, James C. Whorton).

Manchester Courier and Lancashire General Advertiser, 1 December 1900 (https://ancoatsdispensary100.wordpress.com/2014/12/14/78-a-barrel-of-poisoned-beer/).

The Salford Reporter of 1st December 1900 records "The discovery that poison lurks in one of the most popular of the nation's beverages has been a rude shock to the inhabitants of Salford and neighbourhood" (www.weasteheritagetrail.co.uk/salford-people/biographies/entry/the-salford-poisoned-beer-scandal.htm).

Overigens werd in 1902 een arseenvervuilking gevonden in 'Pure Beer', waarbij de gesrtemout wat gedroogd met coke (The Arsenic Century: How Victorian Britain was Poisoned at Home, Work, and Play, James C. Whorton).

The Manchester arsenic-in-beer epidemic of 1900-1 was a serious and widespread food poisoning outbreak affecting several thousand people across the North-West and Midlands, with many cases proving fatal. .... the con- sensus of expert opinion was that beer was the means by which the poison had reached the public, and brewing sugar, contaminated by impure sulphuric acid was the source of the arsenic...Although it was already understood that the use of contaminated sugar was not confined to one brewery, Tattersall's ongoing investigations revealed that Bostock's supplied approximately 200 breweries in the north of England and the Midlands.50 Reynolds wrote to the newspapers on 27th November, stating that he just bought beer openly from a shop and found it contaminated with arsenic....By January, 1900, the extent of the arsenic epidemic had been largely realised. Approximately 3,000 persons had been diagnosed as suffering from chronic arsenic poisoning as a result of drinking contaminated beer, with upward of 70 cases proving fatal; the final total number of sufferers was estimated at 6,000... Arsenic epidemics occurring elsewhere in the north-west and midlands, generat- ed similar policies of co-operation between local authorities and brewers,

based upon the systematic analysis, withdrawal and destruction of contami- nated beer and brewing ingredients (www.breweryhistory.com/journal/archive/132/Death_in_a_beerglass.pdf).

Tja vergiftig bier van vergiftige suiker, maar wie is verantwoordelijk?

The inquest next focused on where, between Bostock's and Nicholson's, ulti- mate responsibility lay. In the event, the history of transactions between the two companies proved to be so confusing as

to defy the jury's best efforts to unravel and apportion blame. Bostock's main- tained that the fault lay with Nicholson's for supplying them with impure acid when they had always previously supplied pure; Nicholson's, held that since Bostock's contract did not specifically request pure acid, they had been quite justified in supplying impure. What did become clear during cross-examination was that Nicholson's explanation for the change of supply was highly question- able, and Bostock's procedures for testing raw materials and finished products were inadequate...The irony is that the condemnation was equally applicable to the brewing indus- try. If Bostock's chemists were lax in failing to test their products, then the same was true of the brewers, whose only defence was ignorance and the misplaced assurance that this had never happened before. (www.breweryhistory.com/journal/archive/132/Death_in_a_beerglass.pdf).

Bijzonder dat een arseenvergiftiging kon gebeuren in 1900, aangezien al enkele jaren daarvoor een vergelijkbaar iets was gebeurd met snoepjes:

One tragic case from 19th century England saw 20 children killed and more than 200 people injured when a batch of peppermint candies was accidentally tainted with arsenic. The incident, which led to changes in laws governing food preparation in England, came to be known as the Bradford Sweets Poisoning of 1858.

William Hardacre (sometimes spelled “Hardaker”), known to locals as Humbug Willie, sold peppermint candies from a stall in Green Market. His supplier was a spice dealer named Joseph Neal, who bought his supply of gypsum from a druggist by the name of Charles Hodgson (http://www.oddlyhistorical.com/tag/arsenic-poisoning/).

On October 30, 1858, William “Humbug Billy” Hardaker inadvertently poisoned over 200 people. His peppermint humbugs were laced with arsenic. The incident reflected the state of Victorian pharmacology and led to law reform (http://steampunkchicago.com/articles/humbug-billys-poison-candy/).

The 1858 Bradford sweets poisoning was the arsenic poisoning of more than 200 people in Bradford, England, when sweets accidentally made with arsenic were sold from a market stall. Twenty-one victims died as a result. The event contributed to the passage of the Pharmacy Act 1868 in the United Kingdom and legislation regulating the adulteration of foodstuffs.

William Hardaker, known to locals as "Humbug Billy", sold sweets from a stall in the Greenmarket in central Bradford (now the site of Bradford's Arndale Centre). Hardaker purchased his supplies from Joseph Neal, who made the sweets (or "lozenges") on Stone Street a few hundred yards to the north. The lozenges in question were peppermint humbugs, made of peppermint oil incorporated into a base of sugar and gum. However, sugar was expensive (6½d per pound) and so Neal would substitute powdered gypsum (½d per pound) — known as "daff"— for some of the required sugar. The adulteration of foodstuffs with cheaper substances was common at the time and the adulterators employed obscure nicknames ("daff", "multum", "flash", "stuff") to conceal the practice.... Originally the first deaths—those of two children—were thought to be owing to cholera, a major problem in Britain at the time; but the growing number of casualties soon showed that the purchase of lozenges from Hardaker's stall was the cause, and from there the trail led to Neal and Hodgson (https://en.wikipedia.org/wiki/1858_Bradford_sweets_poisoning) (www.historic-uk.com/HistoryUK/HistoryofBritain/Dying-for-Humbug-the-Bradford-Sweets-Poisoning-1858/).

On an October night in 1858, a sweet seller by the name of "Humbug Willie" sold peppermint-flavored hard candies to passerby from a market stand on Bradford, England. Humbug Willie sold close to 1000 individual pieces of candy that night.

Within days 25 people died, while at least 90 adults and 50 children became extremely ill. Counted among the stricken was Humbug Willie himself, who became sick from handling his own candies.

Results of a criminal investigation determined that each peppermint treat contained two times the lethal dose of arsenic (about half a gram)...Sugar is expensive — so Joseph Neal, the distributor of the candies, sought to cut his costs, by inserting several kilograms of "daft" as a substitute for sugar. "Daft" was a substance that ranged in composition from calcium sulphate to pulverized lime to gypsum — none of these are tasty, but they're all perfectly safe.

...When Joseph Neal sent an assistant to purchase some daft from a local pharmacist, a series of errors occurred. Charles Hodgson, the pharmacist who owned the establishment left his recently appointed apprentice, William Goddard, in charge of the store.

Goddard initially sent Neal's assistant away as he did not know the precise location of the daft, but Neal's assistant persisted, leading Goddard to contact his sick boss. A poor set of directions sent scurrying Goddard to the backroom, where he found a barrel of unlabeled white powder. After expending considerable effort in prying the barrel lid off, Neal's assistant left with twelve pounds of the white substance.

This trip to the cellar marks a one of several the grievous errors committed in the Bradford poison scandal. The white powder Goddard sold, arsenic trioxide, did not carry with it a proper label and sat amidst a number of other barrels containing white powders. Additionally, The Sales of Arsenic Act required a color additive to be mixed in with arsenic nitrate to help identify this deadly poison — and that was the only artificial additive left out in this tragic story.

The powder next entered the able hands of James Appleton, a local sweet-maker employed by Neal. Appleton combined forty pounds of sugar, twelve pounds of arsenic trioxide, four pounds of gum, and peppermint oil, to create at least forty pounds of peppermint lozenges.

James Appleton worked for six hours to create the batch, with this prolonged contact with arsenic trioxide leaving him ill for several days with vomiting and pains in his appendages. Appleton never considered that the "daft" could be the source of his illness....The Bradford poison scandal led to an increase in regulations regarding the handling of chemicals by druggists via the UK Pharmacy Act of 1868. The Pharmacy Act in addition to the 1860 Adulteration of Food and Drink bill changed the manner by which ingredients could be used and combined, aiming to ensure the health of consumers (http://io9.gizmodo.com/5919191/when-arsenic-peppermints-poisoned-nearly-200-people-in-a-single-night) (www.historic-uk.com/HistoryUK/HistoryofBritain/Dying-for-Humbug-the-Bradford-Sweets-Poisoning-1858/). All involved were subsequently charged with manslaughter but none were convicted. The Bradford poison scandal led to new legislation in order to protect the public from any similar tragedy. The 1860 Adulteration of Food and Drink Bill changed the manner by which ingredients could be used, mixed and combined. The UK Pharmacy Act of 1868 introduced more stringent regulations regarding the handling and selling of named poisons and medicines by druggists and pharmacists. The abolition of the sugar tax in 1874 meant sugar became affordable to all. (www.historic-uk.com/HistoryUK/HistoryofBritain/Dying-for-Humbug-the-Bradford-Sweets-Poisoning-1858/). But the change that did the most to end the practice of mixing sugar with daft came in 1874, when the sugar tax was abolished. Prices dropped in the wake of the decision, and it was no longer necessary to cut the sweet stuff with other, potentially deadly, substances to make it affordable (www.oddlyhistorical.com/tag/arsenic-poisoning/).

Edwyn Barclay Head of Barclay & Perkins Brewery in Park Street Southwark (http://obc1897.org/about%20us/history.html). Edwyn Barclay. During 1909-1910, the Institute of Brewing knew him as zealous President, and in his position as Chairman of the Advisory Sub-Committee on Hop he played constructive part in the development of the hop research scheme....He was always deeply concerned with the fortunes and progress of the great firm which bears his name and which is one of the chief pioneer companies in the development of public house improvement (http://onlinelibrary.wiley.com/doi/10.1002/j.2050-0416.1930.tb05232.x/pdf).

The comments of Edwyn Barclay, looking back from 1910 reflect this: ‘… the most far-reaching innovation was the starting of a laboratory in the brewery. Constant analysis of all materials has, of course, given an accurate knowledge which has led to many improvements and alterations’. There are no published data on the growth in the numbers of scientists employed in breweries. From examination of brewery archives, obituaries, trade and scientific journals, membership lists etc my provisional estimate is that in 1900 there were around 20 consulting chemists who specialised in brewing practising in the UK.

By 1910 the numbers of consultants had not increased, but the number of dedicated brewers' chemists operating inside breweries had more than doubled to perhaps as many as eighty (www.breweryhistory.com/journal/archive/123/Science.pdf).

Tied house

MR. BARCLAY, with great frankness and great moderation, pleads that perhaps the fact that he knows all about "tied houses" may serve as a sufficient excuse for writing about them. In the first place, he shows, and quite convincingly, that the economic origin of the "tied house" is to be sought in the legislation which has sought to restrict the numbers of the public-houses. We do not hear of tied tea-shops, because anyone may open a tea-shop where and when he pleases. It is not worth while to buy up a particular tea-shop for the sake of securing its custom when a rival establishment may be opened next door. A very small capital is needed to start a tea-shop, and so anything in the nature of a monopoly in the business is out of the question, even in a comparatively restricted area. In the same way, from the time of the passing of the Duke of Wellington's Act in 1838 to 1869, it was easy to open a beer-house, and no monopoly value attached to one. When Parliament began to restrict the numbers of public-houses, it became important for the brewers to keep open the channels for their trade. Then, about the year 188o, the "tied house" became a feature of the trade. Licenceholders entered into agreements with breweries, by way of tenancy or loan, and a covenant in the agreement was an undertaking to purchase liquor only from the contracting company. In many parts of the country the licensee is not a tenant working on his own account for a profit, but a servant of the brewery company that employs him—like a branch manager of a bank, or the manager of a branch shop belonging to a big drapery company. Whether they are good or bad, "tied houses" are the direct and inevitable result of the efforts of the Legislature to limit the number of licensed houses. The fewer they are the more essential it is that these necessary outlets for their trade should be secured by the brewers. In default of such a precaution, a company which confined itself to the production of good beer might have easily have found itself starved for want of custom even in its own neighbourhood.Having thus shown that the institution of the "tied house" was a measure of self-defence forced upon the brewers by the action of Parliament, MR. BARCLAY goes on to consider whether the result has been in any way prejudicial to the public (http://archive.thetablet.co.uk/article/5th-june-1909/5/topics-of-the-day).

Barley, hop and installations

Breeding of hybrid strains of barley originated in 1905 with the crossing of the varieties Plumage and Archer by E. S. Beavan to give a new variety destined to dominate the malting crop from the 1920s

to the 1940s.

E.S. Salmon's hop breeding programme which started the worldwide movement to improved varieties began at Wye College in Kent in 1906 (in 2015 door Imperial College verkocht aan Telereal Trillium).

Also in 1906, Ludwig Nathan was granted an English patent58 on a vessel with a ‘rigid cylindrical iron shell [and] a glass lining made up of curved glass plates' for use in brewing; the first step towards the cylindro-conical fermenter which sixty years latter would start to come into its own.

Aluminium was used for fabrication of fermenters and storage vessels in Germany in 1909 and a year later in the UK; and the metal would have a certain vogue for a couple of decades until stainless

steel took over.

In 1911 Leo Wallerstein, a first generation GermanAmerican consulting brewers' chemist, noting the increasing propensity of Americans to store their beer in the icebox, came up with a method for chillproofing beer to stop it going hazy in the fridge by treating it with proteolytic enzymes in the brewery.

Walter Scott of Ansells in Birmingham patented his eponymous yeast plant in 1913. In this system yeast is drawn off from an open fermenting vessel under vacuum, forced through a filter press and the filtrate returned to the fermenters.

...

If you go into any large modern brewery today, including those few which still brew ale, you will see equipment originally designed for use with bottom-fermentation and it is frequently manufactured by German firms.

Lauter tuns are to be found everywhere.

But all is not as it seems at first glance.

Outside Germany and the Czech. Republic lauter tuns are seldom used in complicated decoction mashing regimes, rather programmed infusion mashing is the norm; you don't see many mash coppers any more. Mash filters for ultra swift processing are also increasingly replacing

lauter tuns and they have their origins in Belgium. The ubiquitous cylindro-conical fermenter originates in Switzerland, not Germany; Ludwig Nathan was from Zurich. But, there is no denying that lager, cold-produced bottom-fermented beer, has encircled the world. With sales buoyed by increasing consumption in developing countries, lager is truly the world drink (www.breweryhistory.com/journal/archive/123/Science.pdf).

Currently, the production of beer in modern breweries most commonly use fermentation in covered cylindrical-conical tanks (CCT or CCF). They are cylindrical vessels with a conical bottom in which are used for primary fermentation (and the further fermentation continues in lager tanks), or the entire fermentation process, including maturation ( lagering tanks are not used ).

Compared to traditional open fermentation vats CCT´s have several advantages (www.czechminibreweries.com/production/brewery-components/cold-block/cylindrical-conical-fermentation-tanks/).

A cylindroconical fermenter is a scaled-down version of what commercial brewers call a uni-tank. The “uni” refers to the fact that the beer can undergo primary fermentation and conditioning in the same tank. With flat-bottomed fermenters, the beer needs to pumped from the fermenter to a conditioning tank. Uni-tanks are very popular in brewpubs and microbreweries — and a few years ago, homebrew-sized conicals started appearing on the market.

The shape of a cylindroconical fermenter is a cylinder with a cone attached on the bottom. A port at the bottom of the cone lets you dump the yeast (and any other sediment) from the bottom of the vessel. Another port is found a little higher on the cone. This one allows you to draw of samples of beer or transfer the beer to another container.

There are many advantages to a stainless conical fermenter (http://byo.com/mead/item/524-cylindroconical-fermenters-advanced-brewing).

UNI tank

A cylindroconical vessel with arched head for fermentation and post-fermentation of beer (www.ziptechnologies.eu/#products-3).

Cylindroconical fermenters remain a craft beer staple... fermentation vessels are used to convert sugars (derived mostly from the malt) into ethanol or alcohol. Yeast is introduced during the fermentation process, and it’s used to convert the glucose (sugars) from the wort (that sweet liquid that comes from mashing the grains), producing both ethanol and carbon dioxide gases (CO2). The yeast also produces a series of minor metabolites such as esters, higher alcohols and acids that contribute positively to flavor.....Fermentation and maturation can be carried out in a variety of tanks — open or closed, horizontal tanks with manholes or vertical tanks with conical bottoms. We’ve even seen old, converted dairy tanks used for fermentation by clever, budget-conscious brewers. But when it comes to commercial craft brewing products today, fermenters are usually cylindroconical....The original, old world commercial fermenters were open-air square tanks, but today the cylindroconical vessel is the industry staple for the American craft brewing industry. Engineered with a conical bottom and a cylindrical top, these vessels are usually three to four times taller than their diameter, fabricated from stainless steel, engineered with adjustable foot supports and racking. Beer nerds can thank Leopold Nathan, who patented the cylindroconical fermenter in 1927, claiming faster fermentation rates. Financially, cylindroconical vessels offer a bevy of pluses — lower capital costs, lower operating costs and minimized space requirements.

Also, the science says cylindroconical fermenters have many advantages — better mixing due to convection currents set up by rising gas bubbles, ease of temperature control, ease of cleaning and easy and and hygienic recovery of yeast from the base (or cone). The cone’s aperture is typically around 70 degrees, an angle that will allow the yeast to flow toward the cone’s apex. We should note that there are some systems that combine fermentation and conditioning in the same vessel.

“That’s called a unitank, which is a fermentation tank that has both primary and secondary fermenting and aging functions in one tank,” explained Brandon LeBlanc, project engineer for JVNW Inc., a vessels and turn-key systems engineering company...First off, fermentation is an exothermic process (a reaction that releases energy), so the rising temperature of the fermentation will need to be carefully controlled. Typically, lagers will be fermented at temperatures between 42˚F and 57˚F for as little time as three to four days but as long as a few weeks. Ales have always been fermented at higher temperatures (59˚F to 68˚F). The resulting ales tend to contain more complex flavors and faster fermentations (at usually two to three days). Fermenter temperature controls for small craft breweries can be as simple as analogue gauges attached to the unit, but for larger systems they can be as complex as advanced digital control panels that run multiple vessels....The excess heat being created must be removed from the fermenter if the temperature of fermentation is to be controlled, which means the fermenter must usually be equipped with a “cooling jacket” to remove heat generated during that exothermic reaction and other ambient temperature factors.....When it comes to sanitation, cleaning-in-place (CIP) fluids are often introduced through the top plate or perhaps at the bottom if ease of access is better below. CIP refers to the mix of chemicals, heat and water that cleans machinery, vessels or pipe work without dismantling the plant. CIP has been around for about 50 years and is used in hygiene critical industries, including food, biotechnology, pharmaceutical, beverage and brewing. Cylindroconical fermenting vessels are almost always cleaned by CIP fluids, using a CIP arm and often a spray ball. Various designs of impact jets are available (www.craftbrewingbusiness.com/equipment-systems/brewing-vessels-reviewed-cylindroconical-fermenters/).

International congress for the brewing and beverage industry – 7 to 9 March 2016, Soest, Germany (www.vlb-berlin.org/en). Deze week is er een congres over bierbrouwtechniek. Daar zullen vast allerlei Duitse brouwgeheimen worden besproken.

Ik had wel eens gehoord dat er gist werd gestolen en via een hoge hoed werd gesmokkeld, maar er zijn nog meer van dergelijke verhalen, zo lees ik in The Sword and the Armour: science and practice in the brewing industry 1837-1914 Ray Anderson:

Pils/Lager all over the world

At the German Brewing Congress of June 1884, the redoubtable Max Delbrück, Director of the Experimental and Teaching Institute for Brewing in Berlin announced ‘With the sword of science

and the armour of practice German beer will encircle the world.’ It was no idle boast. In 1887 beer output in the German states exceeded that in the UK for the first time and Germany became the

largest producer of beer in the world.

Fifty years earlier, when the 18 year old Victoria came to the thrown, it was unthinkable that Germany would hold such a position. Britain was the premier brewing nation, with London's massive porter breweries of ‘a magnificence unspeakable’ in the van.....over 70% of the beer sold is lager - and much of the ale and stout now served in pubs is dispensed at very low temperatures to make it seem more like lager! However, I doubt if Max Delbruck would recognise the lager of unrivalled blandness which now sells the most worldwide as having much to do with what he knew as

German beer (www.breweryhistory.com/journal/archive/123/Science.pdf).

(zie ook Brewer & Distiller International • May 2009 • www.ibd.org.uk Brewing history 25. www.ibdlearningzone.org.uk/article/show/pdf/483/ en www.yumpu.com/en/document/view/4177574/the-sword-and-the-armour-brewery-history-society)

Max Delbrück: Born 16 Jun 1850; died 4 May 1919 at age 68.

Max Emil Julius Delbrück was a German chemist who spent a forty-five year career leading development in the fermentation industry. He established a school for distillation workers, a glass factory for the manufacture of reliable apparatus and instruments, and an experimental distillery. Giving attention to the raw resources, he founded teaching and experimental institutions to improve cultivation of potatoes and hops. He researched physiology of yeast and application in the process of fermentation, production of pure cultures, and the action of enzymes. He started the journals Zeitschrift fur Spiritus-Industrie (1867) and Wochenschrift für Brauerei, for the alcohol and brewery industries, which he co-editted. His nephew, also named Max Delbrück, became a microbiologist who won the Nobel Prize in Physiology or Medicine in 1969 (http://todayinsci.com/6/6_16.htm#DelbruckMax1850). Lactobacillus Delbrücki herinnert aan hem (Wie wir das Leben nutzbar machten: Ursprung und Entwicklung der Biotechnologie, Robert Bud).

Mit dem Schwerte der Wissenschaft, mit dem Panzer der Praxis, so wird Deutsche Bier die Welt erringen.

(With the sword of Science and the armour of Practice, German beer will encircle the world.)

— Max Delbrück

From address about yeast and fermentation in the brewery, to the German Brewing Congress (Jun 1884) as Director of the Experimental and Teaching Institute for Brewing in Berlin. In 'Ueber Hefe und Gärung in der Bierbrauerei', Bayerische Bierbauer, 1884, 19, 312. As cited in Ray Anderson, Brewery History (Summer 2006), No. 123, 55. Indeed, as quoting Anderson, “In 1887 beer output in the German states exceeded that in the UK for the first time and Germany became the largest producer of beer in the world.” Using Google translation, the word “armour” might also be read as “breast-plate.” (http://todayinsci.com/QuotationsCategories/B_Cat/Beer-Quotations.htm).

Techniek en spionage

Once the steam engine became available, London brewers where understandably keen to adopt it. By

the turn of the century the improved engines of Boulton and Watt and others had been installed in all but one of London's major breweries and horses and men were reduced in number.

Quantitative measurement crept into brewing from the mid 18th century with the application of the thermometer by Michael Combrune, and then the hydrometer, in the form of the saccharometer, by John Richardson.

...

Until the 1840s bottom-fermentation was unknown outside Bavaria and Bohemia (where it had been practised since about 1400). It was then, instigated to an extent by the efforts of Gabriel Sedlmayr jnr from the Spaten Brewery in Munich and Anton Dreher from his family brewery at Schwechater just outside Vienna, that lager began to spread. On a trip to Britain in 1833 the pair had indulged in what has been described as industrial espionage, learning the use of the saccharometer and thermometer and the techniques of large scale brewing. They were not above rather underhand behaviour such as secretly taking samples in breweries using hollow walking sticks. On their return home Sedlmayr and Dreher became apostles for lager and applied what they had learnt in Britain's more advanced ale breweries to the production of bottom-fermented beers. The first pale straw coloured lager, for the product of Munich was dark brown in colour and that of Vienna a reddish brown, is usually ascribed to Josef Groll a German brewer working in Pilsen in October 1842. Lager was first produced in Norway in 1843 and more famously Jacob Christian Jacobsen made the long journey from Copenhagen to the Spaten brewery in 1845 and obtained some yeast which he carefully preserved in his hat box on the return journey and used it to produce his first lager (a dark one) in 1846. A year later he built a new brewery on a hill overlooking Copenhagen and called it after his young son Carl and its location: hence Carlsberg. Lager was making significant inroads in north Germany by 1850 and Gerard Heineken, seeing which way the wind was blowing, switched from ale to lager brewing in Amsterdam in 1869.

Lager was to be found on the other side of the Atlantic from the 1840s. Frederick Pabst, Frederick Miller and Joseph Schlitz exploited Lake Michigan's ice for lager production. Bernard Stroh similarly on Lake Erie. Ebrehard Anheuser and Adolphus Busch utilized the cool caverns of St Louis. Adolph Coors the Colorado mountains. From the 1870s these German-Americans developed a new style of lager brewed with readily available cereals, notably maize (corn) and in Anheuser-Busch's case rice as diluants for the high nitrogen six-rowed barleys grown in the USA. These adjuncts were used unmalted and were gelatinised before addition to the malt mash. Although banned in Bavaria, there was nothing new in the use of unmalted adjuncts, but what was different from mainstream European practice was the high level of use. The Americans used them at levels of 50% or more of the grist. This coupled with the development of an accelerated brewing process where storage time was minimised and filtration used for clarification, led to the development of unique very pale coloured, delicate, beers (www.breweryhistory.com/journal/archive/123/Science.pdf).

November 2015 was an auspicious month for the American beer industry. According to data provided by the Brewers Association the number of breweries in the United States reached 4,144. At no other time in our country’s history has America had so many breweries. The previous high was 4,131 in 1873. ...In commenting on reaching a record high number of breweries Bart Watson, the Brewers Association’s economist, stated that “this is a remarkable achievement, and it’s just the beginning”. Some may find the statement by Watson to be provocative as it suggests that the number of breweries is set for continued significant growth (http://www.thebeerprofessor.com/?p=1477#more-1477). De uitspraak van Watson kan wellicht ook wel worden vergeleken met die van Delbrück, maar Max Delbrück was nog bouder, aangezien Amerikaans bier reeds behoorlijke aanzien heeft in de brouwerswereld.

1873 – the year in which Jules Verne’s Around the World in 80 Days was published in France, Levi Strauss and Jacob Davis patented the first blue jeans with copper rivets, Prince Edward Island became the seventh Canadian Province, nineteen students attended the opening class at The Ohio State University, and Jesse James and his gang committed the world’s first robbery of a moving train near Adair, Iowa.

But what about beer? What was happening in the world of beer in and around 1873? While the number of breweries today is almost identical to 1873 the population of the United States was considerably smaller back then – ~40 million, compared to ~320 million today. Do the math and that means that in 1873 there was 1 brewery for every 9,683 people, compared with 1 brewery for every 77,220 people today. In 1873 there were 8.9 million barrels of beer produced in the United States. Today’s craft brewers produce 22.3 million barrels. In 1873 the top three beer producing states were New York (2.9 million barrels), Pennsylvania (1.1 million barrels), and Ohio (0.8 million barrels). Today the top three beer producing states (for craft beer) are Pennsylvania (4.1 million barrels), California (3.4 million barrels), and Colorado (1.7 million barrels).

The breweries of the 1870s were smaller than the craft breweries of today. In 1873 the average annual output of American breweries was 2,154 barrels. Today’s craft brewery averages 5,381 barrels. This can be partly explained by the fact that a number of today’s breweries have a much larger geographic reach than the breweries of the 1870s (www.thebeerprofessor.com/?p=1477#more-1477). Today’s craft breweries have access to brewing techniques and transportation technology and infrastructure that were unavailable (or was just becoming available) to brewers in the 1870s. The process of pasteurization*, which kills harmful bacteria in the beer with the result that it does not spoil so quickly, was discovered* by French chemist Louis Pasteur* in 1864. In was during the 1870s that Anheuser-Busch, and other brewers, started to pasteurize their beer. Pasteurization opened up the possibility of brewers shipping their beer beyond very local markets (www.thebeerprofessor.com/?p=1477#more-1477). * Over pasteurisatie zo meer...

From the 1860s, the increasing availability of efficient artificial refrigeration freed lager brewers from the need for natural ice. Lager and ale brewers alike adopted all year round brewing. Refrigeration was initially used to produce ice but was soon applied to direct cooling via expansion coils (www.breweryhistory.com/journal/archive/123/Science.pdf).

Anheuser-Busch was one of the first companies to transport beer nationwide using railroad refrigerator cars (https://en.wikipedia.org/wiki/Anheuser-Busch).

When beer was transported to more distant markets it was done so by rail car. The rail network of 1870 was confined primarily to those parts of the country that lay east of the Mississippi River.

Another key transportation innovation that made its appearance in the 1870s were refrigerated rail cars. Anheuser-Busch started using refrigerated rail cars in 1874 and by 1877 had a fleet of forty rail cars, manufactured by the Tiffany Refrigerator Company of Chicago, that were used to deliver beer to ever more distant markets. The first refrigerated rail cars were cooled by using huge amounts of ice. This meant that there had to be Ice Houses (where rail cars would replenish their ice supplies) located at strategic locations along the rail track. It was not until the early-1880s that Anheuser-Busch adopted artificial refrigeration systems, thus eliminating their dependence on ice. By 1879 Anheuser- Busch’s beer was available in all thirty-eight states in the Union.

So what type of beer were Americans drinking in 1873? By then lager was the most popular style of beer in the United States. Lager was introduced to the United States by German immigrants who started coming to the United States in large numbers beginning in the 1830s. Prior to that British-styled ales and stouts had dominated the American beer market. By 1880 over eighty percent of the brewers in the United States were German immigrants. While the lagers brewed by the first-wave German immigrants were replicas of those brewed back in the old country the American beer drinker demand lager that was blander and smoother – hence the utilization by the brewers of cheap adjuncts, particularly rice. By the end of the 1870s lager was well on its way to becoming Americanized (www.thebeerprofessor.com/?p=1477#more-1477).

During the 1870s, Adolphus Busch toured Europe and studied the changes in brewing methods which were taking place at the time, particularly the success of pilsner beer, which included a locally popular example brewed in Budweis. In 1876, Busch introduced Budweiser, with the ambition of transcending regional tastes. His company's ability to transport bottled beer made Budweiser the first national beer brand in the United States, and it was marketed as a "premium" beer.

The company was renamed Anheuser-Busch Brewing Association in 1879; in 1880, Adolphus Busch became company president upon Anheuser's death. The Busch family fully controlled the company through the generations until Anheuser-Busch's sale to InBev in 2008 (https://en.wikipedia.org/wiki/Anheuser-Busch).

Lager now became a world drink. The first successful commercial brewery in Japan, the Spring Valley Brewing Company set up in Yokohama by an American W. Copeland in 1869, evolved into the Kirin Company and brewed lager. German brewmasters brought brewing to China for the first time in the 1870s; Tsingtao lager from what is now China's biggest brewer, was an early product. Hampered by lack of suitable materials and the climate, local beer production in Australia only started to outstrip imports in the 1870s. Lager brewing reached the country in the late 1880s, with the American émigré Foster Brothers beer, brewed by the German brewmaster they brought with them using domestic cane sugar as an adjunct to malt, going on sale in Melbourne in 1889.

Lager had been imported into Britain since about 1850 and the first tentative steps at brewing what at least was called lager, may have been taken place within a decade or so thereafter but the evidence for these early attempts is sketchy. Experimental brewing of genuine lager took place at William Younger's Holyrood brewery in 1879 and what was probably the first purpose built lager brewery in the UK was built in Wrexham in 1882. Tennents started brewing lager in Glasgow in 1885. But it remained very much a niche drink in the UK (about one percent of the UK market in 1960, by which time lager made up c. 20% of the market in Scotland) (www.breweryhistory.com/journal/archive/123/Science.pdf).

Louis Pasteur, de microscoop en gist

Louis Pasteur, de microscoop en gistLouis Pasteur (December 27, 1822 – September 28, 1895) was a French chemist and microbiologist renowned for his discoveries of the principles of vaccination, microbial fermentation and pasteurization. He is remembered for his remarkable breakthroughs in the causes and preventions of diseases, and his discoveries have saved countless lives ever since. He ... created the first vaccines for rabies and anthrax. His medical discoveries provided direct support for the germ theory of disease and its application in clinical medicine. He is best known to the general public for his invention of the technique of treating milk and wine to stop bacterial contamination, a process now called pasteurization. He is regarded as one of the three main founders of bacteriology, together with Ferdinand Cohn and Robert Koch, and is popularly known as the "father of microbiology". (https://en.wikipedia.org/wiki/Louis_Pasteur,

www.biography.com/people/louis-pasteur-9434402).

Concurrent with the spread of lager brewing came more emphasis on a scientific approach to brewing, the most famous early practitioner being Louis Pasteur. Until Pasteur carried out his investigations on wine and beer fermentations in the 1860s and 1870s and showed the importance of eliminating deleterious bacteria, there was little practically useful advice available to brewers on how to prevent their beers unaccountably going off. In a wider context, it was through the investigation of the production of wine, vinegar and beer that Pasteur established the importance of micro-organisms in causing disease. The far reaching significance of Pasteur's work on fermentation can thus not be doubted.

What is less clear is the actual impact his work had upon fermentation practice and brewing in particular. Pasteur's Etudes sur la Biere published in 1876 and translated into English as Studies on

Fermentation in 1879, is often cited as revolutionising the industry. This is something of an exaggeration. The fermentation technology he devised, which essentially involved aseptic procedures in a closed vessel, found very limited application. His advocacy of the danger of aerial infection in breweries found more adherents, but in time it became clear that a greater hazard came from contact of wort with dirty surfaces and the drip of germ-ridden condensations. Even the heat treatment technique which bears his name and which became so widely used was not recommended by him for use with beer on the grounds that it spoilt the flavour*. It is in his advocacy of the practical utility of science which he communicated in a very high profile manner, rather than in the detail of Pasteur's

work on beer where we may detect his real impact on the brewing industry. One undoubted practical outcome of Pasteur's work, however, was the growing adoption of that great Victorian gentleman's high tech. plaything, the microscope, for use in breweries. Pasteur was not the first to use a microscope in a brewery, but it was certainly he who popularised it.

Meer wetenschappers met microscoop en gist, stikstof, pH, microbiologie en botanica

A technology which was quickly accepted in most quarters of the brewing world was pure yeast culture introduced by Emil Christian Hansen at Carlsberg in 1883. Where Pasteur had identified bacteria as the causes of brewing problems, Hansen extended this to the presence of harmful yeasts. Pasteur had purified yeasts by acid washing to kill the bacteria. Hansen selected a single strain of yeast from the unreliable and variable mixed cultures then in use in the brewery and in so doing significantly improved the consistency of fermentations and the reproducibility of beer flavour (www.breweryhistory.com/journal/archive/123/Science.pdf).

Emil Christian Hansen, 1842-1909, dansk mikrobiolog og laboratorieforstander

Emil Chr. Hansen (1842-1909), fermentation physiologist and head of the Carlsberg Laboratory, developed a method for purifying yeast that would revolutionise the yeast industry.

(http://denstoredanske.dk/Mad_og_bolig/%C3%98l,_vin_og_spiritus/Vin_generelt/Emil_Christian_Hansen, www.carlsbergfondet.dk/en/Afdelinger/Carlsberg%20Laboratorium.aspx)

Johan Kjeldahl